[ad_1]

MIT is legendary as a manufacturing facility of concepts. You may additionally name MIT a manufacturing facility for studying. However for one group of scholars over the previous yr MIT has been, in truth, a manufacturing facility.

The crew of graduate college students designed and constructed — fully inside an MIT lab — an meeting manufacturing facility for a low-cost, reconfigurable desktop fiber extrusion system.

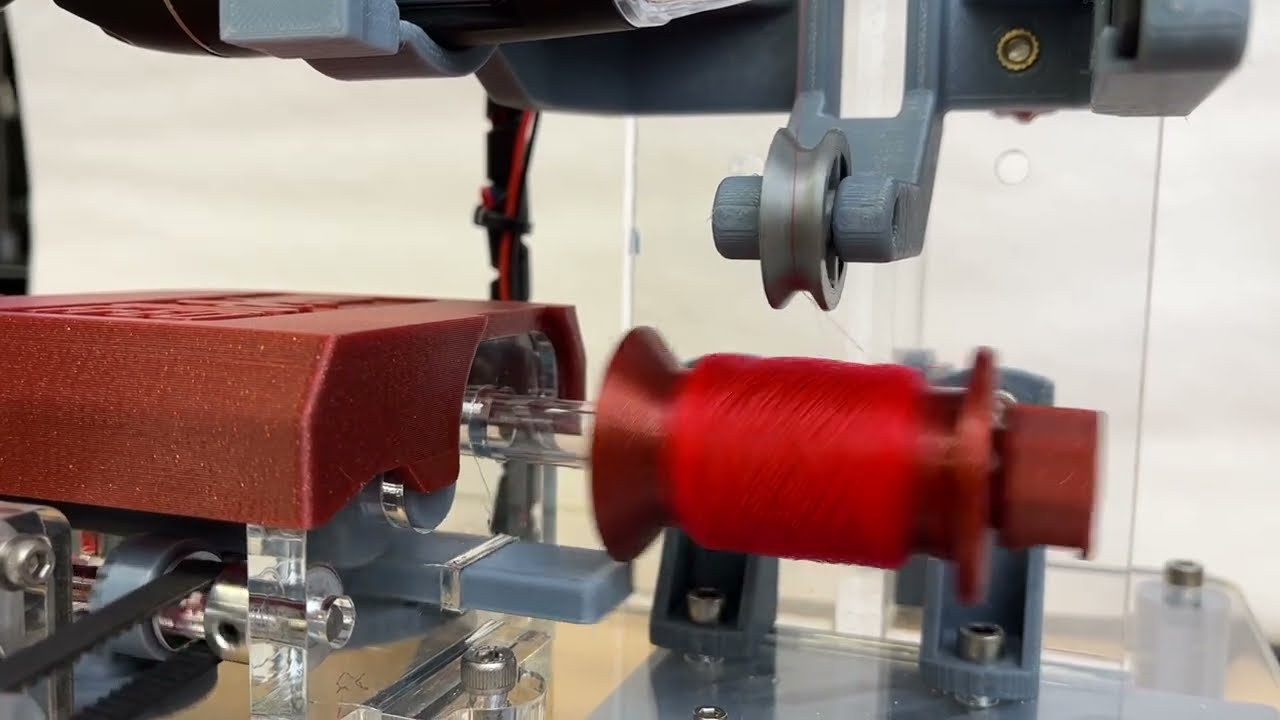

The manufacturing facility was the scholars’ thesis undertaking within the Grasp of Engineering in Superior Manufacturing and Design. The crew reworked the fiber (Fr) extrusion (E) machine (D), or FrED, from a single $5,400 proof-of-concept unit to 25 models manufactured at a price of about $200 every — a 96 % discount in value.

The FrEDs are able to be delivered to superior manufacturing college students in Monterrey, Mexico, as a part of a long-term collaboration between Tecnológico de Monterrey and MIT, mentioned Brian Anthony, affiliate director of MIT.nano and college lead for the Trade Immersion Program in Mechanical Engineering, who suggested the scholars.

The units and the manufacturing facility are a part of a “virtuous cycle of training,” Anthony says. “The units will probably be used as a educating instrument in undergraduate and graduate courses at each MIT and Monterrey Tec this tutorial yr, in addition to in manufacturing workforce skilled training in Mexico. The manufacturing facility at MIT itself will proceed to function a platform to show our college students about assembly-line design and different manufacturing ideas.”

“A glue gun on steroids”

The unique FrED was in-built 2017 by Anthony’s PhD pupil David Kim. Feed in glue sticks, and the system extrudes, cools, and spools fiber, guided by sensors alongside the way in which. The compact, comparatively low-cost product teaches college students about manufacturing and management techniques by way of a tool the place they’ll change varied processes to range the ultimate fiber diameter.

This “glue gun on steroids” is an effective instrument for each college students and professionals, Anthony says, as a result of it represents “a steadiness between a course of that’s conceptually simple, however as quickly as you will get underneath the hood just a little bit it may be made very complicated.”

To increase its usefulness and attain, FrED wanted to be even cheaper, simpler to assemble, and extra user-friendly. That’s the place Russel Bradley, Aviva Jesse Levi MNG ’22, Rui Li MNG ’22, and Tanach Rojrungsasithorn MNG ’22 are available.

The graduate pupil crew labored half time within the spring and full time in the summertime to construct and take a look at a brand new FrED prototype, work out a option to manufacture the machine at scale, after which arrange a provide chain and meeting line to construct the 25 models. The brand new FrED takes about 12 minutes to construct out-of-the-box, the crew discovered throughout person testing.

MIT college students create distinctive meeting manufacturing facility for fiber extrusion units

They divided up the work: Rojrungsasithorn managed the manufacturing facility and ensured the fitting tools was in place, Levi labored on the design of extruding the fiber preform and the general construction of FrED, Li developed the fiber and diameter measuring techniques, and Bradley labored on the machine electronics.

The crew discovered a number of methods to convey down FrED’s value. To start with, they switched most of the components from metallic to plastic and used 3D printers to make some components in-house.

The crew skilled some provide chain points associated to the pandemic, however “we sourced a variety of normal components,” Levi explains. “Loads of the gears which might be a part of the extrusion system are off-the shelf, you should buy them at Amazon or McMaster-Carr or these normal web sites, in order that additionally helped.”

As Li labored on the machine’s filament assortment system, which accommodates a number of gears, he discovered that the variation in 3D-printed components “was much more than I anticipated. It was difficult to see that in the true world versus a textbook.”

The brand new design diminished the variety of microprocessors and motors, and altered the costly laser micrometer measurement system, changing it with “an idea that makes use of cameras and machine studying and machine imaginative and prescient principle as an alternative,” says Bradley.

The crew additionally created a set of 3D design recordsdata and normal manufacturing and working procedures so the scholars in Monterrey or different locations “can replicate our manufacturing manufacturing facility, and later generations [of FrED] may be as near ours as attainable,” Rojrungsasithorn notes.

Establishing the manufacturing facility taught the crew one other essential lesson: it may be difficult at first to convey particular person components collectively to work as a system. “Generally there are errors that you just don’t see earlier than you place the whole lot collectively,” Bradley says.

Manufacturing unit futures

The undertaking confirmed for Levi, Li, and Rojrungsasithorn that the subsequent steps of their profession lie in manufacturing and design. Levi took a job as a mechanical design engineer at Tesla, Li is working as a mechanical instrument design engineer at Intel, and Rojrungsasithorn moved again to Thailand to work in his household’s manufacturing facility, which makes racks that retailer components equipped to automotive producers.

Bradley is at MIT for yet another yr, sustaining the manufacturing facility and utilizing it as a educating instrument in a category about manufacturing techniques. Having the manufacturing facility on campus “is actually one thing particular,” he says, as most universities solely have makerspace-type services to create one or two prototypes.

At Monterrey, the brand new FrEDs will probably be used “to show engineers ideas associated to course of management, sensors, machine studying, and manufacturing processes,” Anthony provides, with a watch to sometime establishing a manufacturing facility on the campus in Mexico.

[ad_2]

Source link